For the most demanding pickup truck customers, the 2018 Ford F-Series Super Duty works harder…

History Of The Ford Super Duty Part2

So was the original Super Duty a hit? You could say that. Just five years into production, Ford’s numbers showed that it was selling more diesel-powered trucks than Dodge and GM combined…more than 200,000 per year. However, Ford did anything but sit idle at the top of the mountain. Midway through the 2003 model year, the 6.0L Power Stroke and 5R110 five-speed automatic were introduced, and by ’05 the Super Duty line was treated to a full makeover. To facilitate increased towing and payload capacities, Ford beefed up the frame, completely redesigned the front suspension and steering systems and integrated the first-ever factory trailer brake controller. A fresh look on the exterior complemented a host of interior improvements as well.

As far as building upon the existing Super Duty platform and making it an even more formidable truck, Frank Davis, Ford Vehicle Programs Director for Pickups and Commercial Vehicles at the time, put it best: “The original F-Series Super Duty redefined expectations of what a pickup truck could do, with unprecedented strength and toughness that competitors are still struggling to match. Now, we’ve done it again, raising the bar by focusing on the ways consumers use their trucks.”

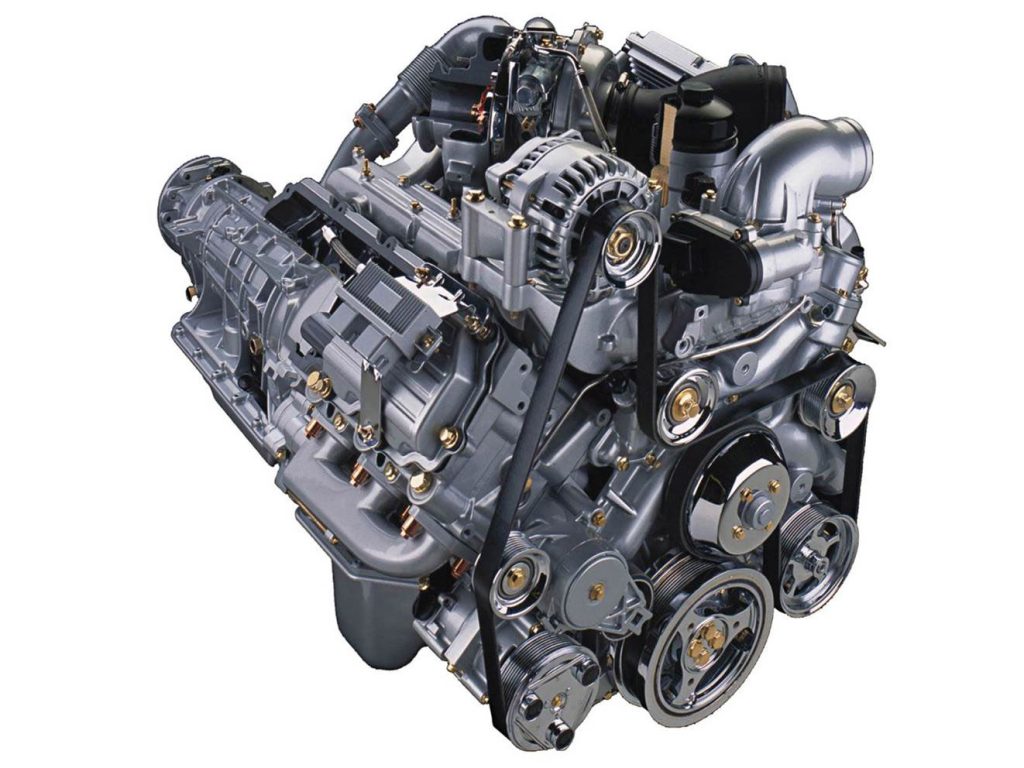

2003: The 6.0L Power Stroke Replaces The Venerable 7.3L

With the deadline to meet new, more stringent NOx emissions standards looming, Ford released its EGR-equipped 6.0L Power Stroke diesel midway through the ’03 model year as the 7.3L’s replacement. Though the 6.0L’s displacement was considerably smaller, its four-valve heads, variable geometry turbocharger and higher pressure HEUI injection system helped it outperform the bigger V-8, and it produced 325 hp and 560 lb-ft of torque right out of the gate. By comparison, the most powerful version of the outgoing 7.3L was 275 hp and 525 lb-ft—but it could only be had in conjunction with the ZF-6 manual transmission.

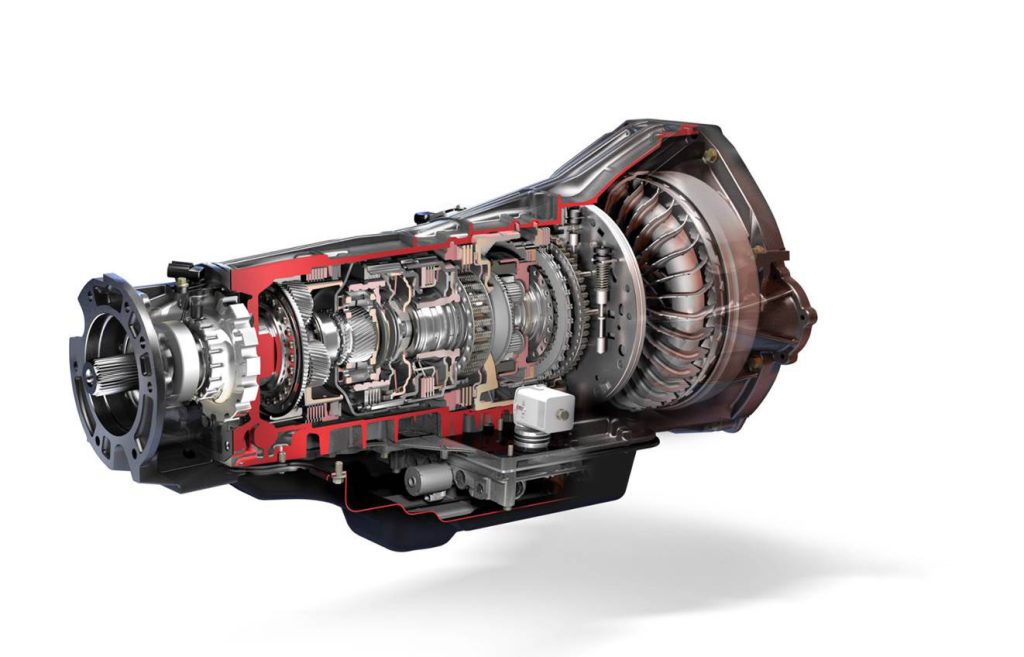

5R110W TorqShift

Embracing modern, electronically controlled transmission technology, Ford debuted the 5R110W TorqShift in 2003 as well. The five-speed automatic was a completely different transmission than the 4R100 it replaced, with an electronic shift solenoid body (in place of a traditional hydraulically controlled valve body) and an adaptive shift schedule strategy aiding in its smooth yet firm gear changes. The TorqShift also featured an integrated Tow-Haul function that altered the shifting strategy to better-accommodate getting heavy loads up to speed as well as bringing them to a halt. On top of all that, the 5R110W was perfectly matched to the 6.0L Power Stroke, always seeming to keep the rev-happy V-8 in the meat of its power curve.

2005: Big Updates and Improved Look

Many of the ’05 Super Duty’s exterior refinements were influenced by Ford’s F-350 TONKA concept, which was very popular at the time. A bolder front grille was the most noticeable change from ’04, which required notching the top of the front bumper to make it fit. Other nuances included: fresh two-tone paint options, 18-inch wheels being available on select models and 20-inch wheels being included on Harley Davidson Super Duty’s, a first in the heavy-duty pickup segment.

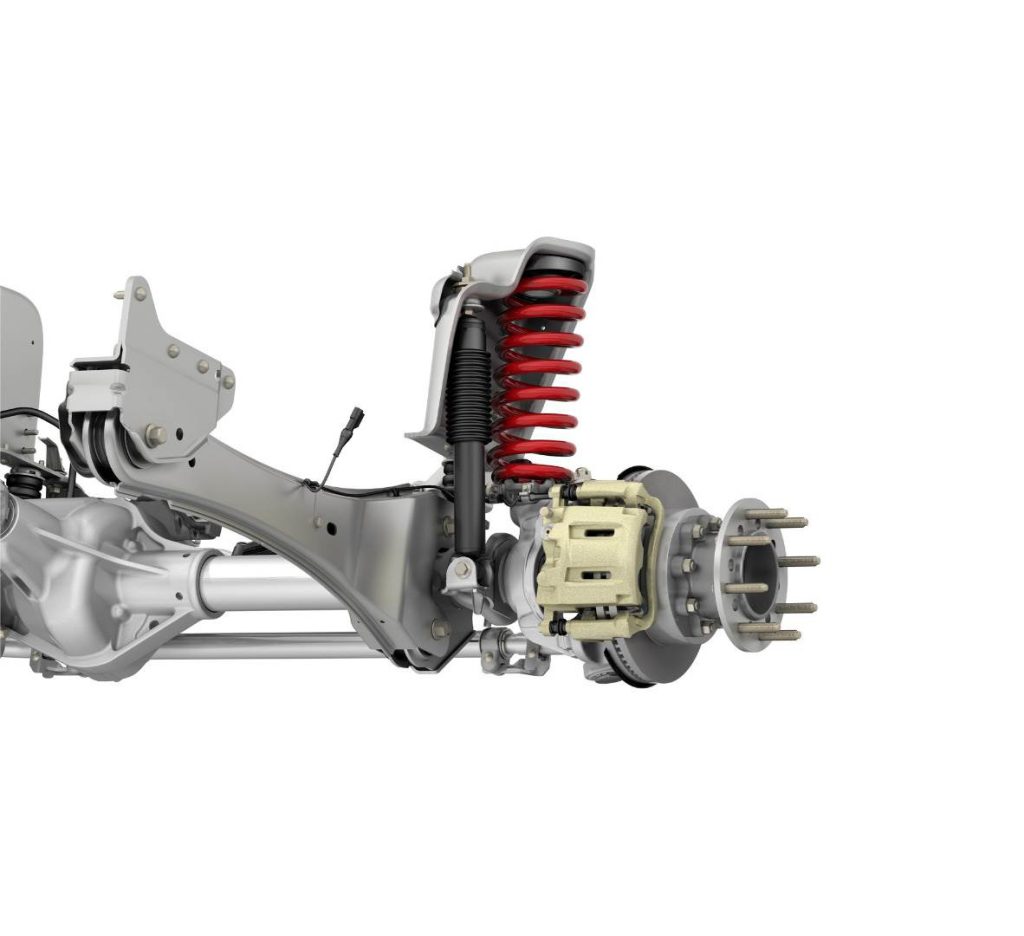

Coil Spring Front Suspension

Perhaps the biggest news for the ’05 revamp was an all-new front suspension system under 4×4 models. A solid axle was still in play, but the leaf springs were scrapped in favor of coil springs with radius arms. The result was a stronger front suspension, better ride quality and, thanks to the new geometry placing the steering arm closer to the wheels, a shorter turning radius was made possible. Out back, the rear suspension didn’t go neglected for the ’05 model year. The rear leafs featured new spring rates, with staggered rear shock absorber geometry being introduced to improve ride comfort.

More Twist

To help the renovated Super Duty platform live up to expectations, the 6.0L Power Stroke was given 10 additional lb-ft of grunt for the ’05 model year, provided courtesy of the engine’s builder, Navistar International. Peak torque now checked in at 570 lb-ft, available at the same 2,000 rpm. Horsepower remained the same at 325, achieved at 3,300 rpm. During this same time frame, various part updates had been (or were being) implemented to rectify several of the 6.0L engine’s reliability and durability shortcomings.

Gas Engine Updates

Falling in line with what consumers had already seen in the F-150 line, the 5.4L Triton V-8 (the Super Duty’s base engine) received 3-valve cylinder heads and variable valve timing in 2005. Power jumped to 300 hp and torque to 365 lb-ft. The 6.8L V-10 was also treated to 3-valve cylinder heads, as well as a power increase. Its 355 hp at 4,750 rpm and 455 lb-ft at 3,250 rpm made it the class-leader in terms of gasoline engines.

Factory Trailer Brake Controller

In a move that screamed “why didn’t they think of that sooner!” Ford introduced the first-ever factory-installed electronic trailer brake controller on its 2005 Super Duty. In knowing that 90-percent of Super Duty owners tow and that 80-percent of them install aftermarket trailer brake controllers, the inclusion of an OEM controller proved Ford was listening to its customers. The edge that the factory trailer brake controller had over aftermarket units was its integration with the truck’s exclusive trailer braking strategy, which would kick in (not allowing the trailer brakes to lock up) if the truck’s anti-lock braking system detected poor traction.

Upfitter Switches (Another First)

On top of the new gauge cluster and instrument panel—both of which were easier to read and use—was another segment first: upfitter switches. Mounted next to the integrated factory trailer brake controller and easily accessible on the dash, the upfitter switches could be tapped into and utilized for the end-user’s specific needs. Like the trailer brake controller, the upfitter switches were a direct result of Ford listening to its commercial truck buyers.

Increased Towing & Payload

If you’re going to own work, you have to offer the highest towing and payload capacities—and that’s exactly what Ford did in 2005. That model year, a properly-equipped single rear wheel F-250 or F-350 could tow 17,000 pounds via fifth-wheel or gooseneck hitch (23,500-pound GCWR) and 15,000 pounds conventional, the highest in the segment. Maximum payload (again, when properly-equipped) checked in at a segment-best 5,800 pounds. These new, class-leading feats were made possible thanks to increased front and rear axle ratings, along with the aforementioned frame reinforcement and suspension changes.

This Post Has 0 Comments