The legendary 7.3 Power Stroke Diesel engine, when properly maintained can provide years of trouble…

POWER STROKE HISTORY-7.3L

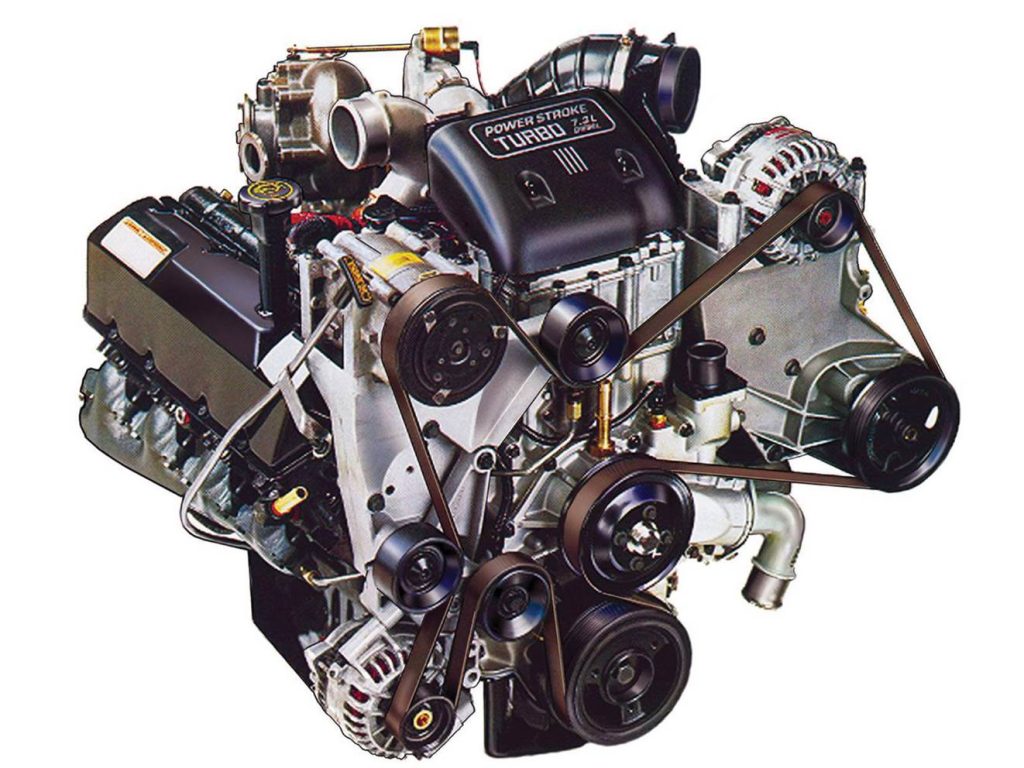

In 1994, the diesel world was changed forever. The 7.3L Powerstroke engine, made by International Navistar, was introduced to Ford Heavy Duty trucks. The 7.3L Powerstroke Diesel engine provided significantly better performance specifications than its 6.9L IDI and 7.3L predecessors. It also offered significantly better reliability than the engine that followed, the 6.0L Powerstroke. The 7.3L Powerstroke was a huge success for Ford, but what made these trucks so special? Here are the key 7.3L Powerstroke engine specifications and design elements that make these trucks so valuable, even today. We’ll also cover model year differences, 7.3 history, and tow ratings.

Ford’s 7.3L Powerstroke engine isn’t nearly as capable as modern diesels, but its simplicity plays a major role in its great success. These engines were built to be big brutes, capable of working for hundreds of thousands of miles without problems. In fact, the 7.3L Powerstroke engine was actually used in medium duty trucks, under a different name, the T444E. It had slight differences, but most internal components remained the same. This is a major advantage as this engine is “overbuilt” for a consumer truck. The 5.9L Cummins diesel has similar advantages, because it was designed for heavy duty hauling and agricultural applications. The durability of the 7.3L Powerstroke is evident in this engines specs and design elements.

For a solid foundation, the 7.3L Powerstroke uses a cast-iron block and a cast-iron cylinder head. These features provide long-term durability and reliability. Six head bolts are used at each cylinder, better securing the heads to the block. This design offers significantly greater clamping force than what’s found on the 7.3L IDI Diesel, or even the 6.0L Powerstroke that replaced the 7.3 Powerstroke.

With hard parts like forged-steel connecting rods and six head bolts per cylinder, the heavy-duty makeup of the 7.3L was obvious. However, what wasn’t so obvious at the time was how well the newfangled HEUI system, which relied on highly pressurized engine oil to make the engine run, would hold up over the long haul. Twenty-five years later, the method of injection employed on the 7.3L—though complex—remains one of the most reliable technologies Navistar and Ford ever used. It’s not uncommon to climb aboard a 7.3L-powered ’99-’03 Ford truck and find more than 400,000 miles on the clock, or an odometer that has since rolled over that (and gone back to 300,000) on a ’94.5-’97 model. This and much more helps explain why Navistar built nearly 2 million of them. Find out all you need to know about the time-tested, revered workhorse that is the 7.3L Power Stroke below.

| Production: | 1994.5 to 2003 | Valvetrain: | OHV, two-valves per cylinder, single cam, hydraulic lifter |

|---|---|---|---|

| Bore: | 4.11 inches | Injection System: | Hydraulic electronic unit injection (HEUI), direct injection |

| Stroke: | 4.18 inches | Injectors: | HEUI (under valve cover) |

| Displacement: | 444 ci | High-Pressure Oil Pump: | Bosch 15-degree (’94.5-‘99), Bosch 17-degree (’99.5-‘03) |

| Compression Ratio: | 17.5:1 | Turbocharger: | Garrett TP38 fixed geometry (’94.5-‘99), Garrett GTP38 (’99.5-‘03) |

| Block: | Cast-iron | Intercooler: | Air-to-air (’99-‘03) |

| Rods: | Forged-steel (’94.5-‘00), powdered metal (’01-‘03) | Horsepower: | 210hp at 3,000 rpm (initial release in ’94.5) to 275hp at 2,800 rpm (‘03) |

| Pistons: | Cast-aluminum | Torque: | 425 lb-ft at 2,000 rpm (initial release in ’94.5) to 525 lb-ft at 1,600 rpm (‘03) |

| Heads: | Cast-iron with six head bolts per cylinder (with sharing) |

7.3L Powerstroke Legendary Reliability

The 7.3L Powerstroke is one of the most reliable Diesel engines ever produced. It’s so reliable even die-hard Cummins and Duramax enthusiasts acknowledge it’s widespread success. This makes them one of the most sought after diesels today. How sought after? Prices for a used 7.3L Powerstroke with 200,000 miles are still upwards of $10,000. That’s a hefty price to pay for a 20 year old truck. Still, most people will tell you they’re worth it. If you’re looking for your first diesel and have a low budget, this is one of the trucks you should consider.

1994.5-2003 7.3L Powerstroke Diesel Performance Specs

Even though we talk about the 7.3L Powerstroke’s simplicity as one of its biggest assets, this engine was highly advanced when it was introduced. A significant portion of the 7.3L Powerstroke engine’s impressive performance specs are attributed to direct fuel injection via Hydraulic electric unit injectors (HEUI injectors). These new injectors were partnered with a high pressure oil pump and a low pressure fuel lift pump. This engine also uses a fixed geometry turbocharger that was significantly more capable than the unit found on 7.3 IDI engines. Late model 7.3s even received an air-to-air intercooler for improved performance because of a larger supply of cold, dense air.

The 1994 Ford Superduty with the 7.3L Diesel engine produces 210 horsepower and 425 lb-ft of torque. That’s an increase of 40 horsepower and 87 lb-ft of torque over the IDI. Adjustments were made also every year to the 7.3l Powerstroke that made these trucks more powerful, especially in later models. Late model 7.3s, 2000-2003 model years, came from the factory with 275 horsepower and 525 lb-ft of torque when paired with the 6-speed manual transmission.

Connecting Rods

Forged-steel connecting rods (above) are believed to be found in all ’94.5-’00 Power Strokes. However, in ’01-‘03 model year engines there was a back-and-forth along the assembly line between powdered metal rods and forged-steel units. Per insider knowledge from Hypermax Engineering, 14,965 “test” sets were installed in engines before Navistar fully committed to using powdered metal rods for the duration of the 7.3L’s production run. After the test-run of powdered metal rods, Navistar reverted back to forged-steel units in order to use up the remaining inventory on-hand at the manufacturing plant. The engine serial breakdown for forged vs. powdered metal rods (PMR) is as follows:

Start of production–1425746=Forged

1425747–1440712=PMR

1440713–1498318=Forged

1498319–final production=PMR

Forged-Steel Over Powdered-Metal

In the performance enthusiast niche, finding out which type of connecting rod an ’01-’03 owner has can determine how far he or she decides to push the horsepower limit of the engine. Forged rods are capable of surviving 600rwhp and tend to bend rather than break, while those with the weaker powdered metal units (which generally break rather than bend) are advised to stay at or below 500rwhp.

Direct Injection

Of all the advancements to debut on the 7.3L Power Stroke, its use of direct injection arguably did the most to usher it into the modern diesel age. Direct injection means that fuel is sprayed directly on top of the piston (the combustion chamber) on the power stroke (no pun intended). No pre-combustion chamber exists (as it does on IDI engines). Each cast-aluminum 7.3L piston features a traditional direct injection, “Mexican Hat” design, a Ni-Resist top piston ring insert for superb wear and corrosion resistance and a plasma-coated top piston ring to prevent cylinder wall scuffing when exposed to sustained high temperature. Beginning in ’99 the piston featured a deeper intermediate ring groove to incorporate a larger intermediate ring width.

Holding Down the Fort

For the type of head-to-block sealing seen in commercial duty applications, the 7.3L Power Stroke benefits from six 12mm diameter head bolts per cylinder (18 per bank). By comparison, its IDI predecessor featured five head bolts per cylinder and its successor (the 6.0L Power Stroke) made use of just four fasteners. The six-bolt arrangement makes the 7.3L capable of handling boost well in excess of 40 psi before head gasket issues are of any concern. Above, a 400,000-mile 7.3L out of an ’02 Super Duty is being fitted with ARP head studs in place of the factory head bolts during an overhaul at San Jacinto, California’s Diesel Tech.

The HPOP

At the heart of the hydraulically-activated HEUI injection system lies this component: a fixed displacement axial-piston pump called an HPOP (or high-pressure oil pump). Its job is to introduce oil volume into the oil rails within the cylinder heads. As oil exits the HPOP, the injector pressure regulator (IPR) pressurizes it as high as 3,000 psi. The stroke of the pump’s internal swash plate determines how much oil volume it can put out. From ’94.5 to early ’99, an HPOP with a 15-degree swash plate was used. Starting in ’99.5 however, the HPOP’s swash plate was increased to 17 degrees, which better supports higher horsepower and larger injectors. We’ll note that timing of the HPOP drive gear is not required. Only the cam and crank are timed with each other.

HEUI Injectors

Physically demanding in size, there are a lot of things happening inside a 7.3L Power Stroke injector. When prompted by the IDM (more on that below), the electronic solenoid at the top is used to pull the internal poppet valve off of its seat, effectively allowing high-pressure oil to enter the injector. The high-pressure oil then forces the intensifier piston beneath it downward, and the nozzle needle beneath that to lift, which pressurizes the fuel present in the plunger cavity. Finally, the nozzle opens and—through a process of multiplication thanks to the intensifier piston possessing a surface area roughly seven times larger than the plunger—the 3,000-psi high-pressure oil figure effectively becomes 21,000 psi worth of fuel pressure in-cylinder.

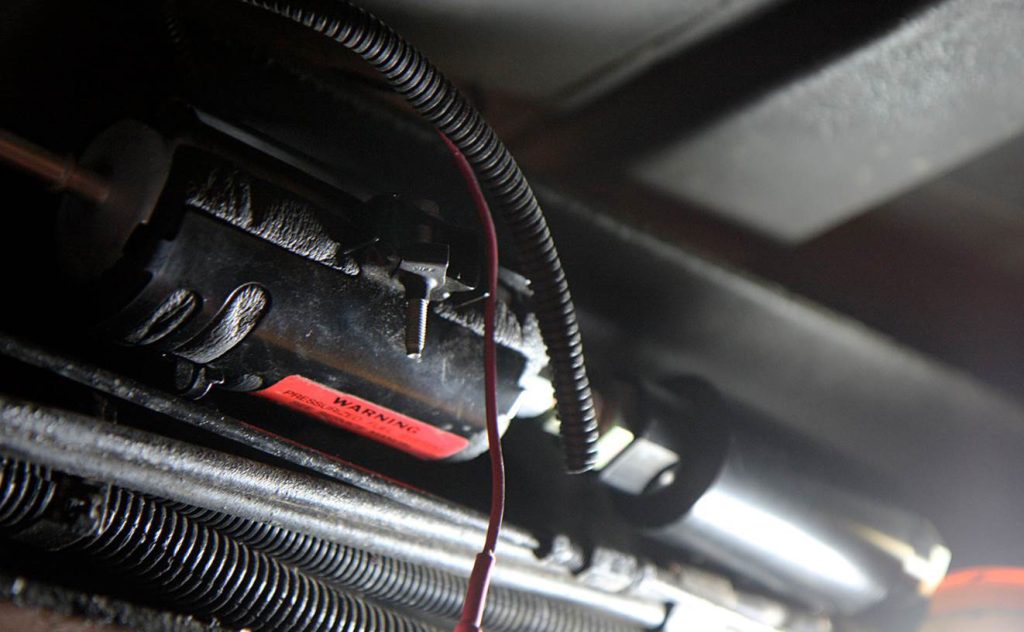

Key Modules

These two modules are the injector drive module (IDM, left) and the powertrain control module (PCM, right). In terms of the injection system on the 7.3L Power Stroke, the PCM calls upon the IDM to energize the injector solenoids via a 100 to 120-volt current pulse (voltage varies depending on the model year of the engine), with the PCM also determining the timing and duration of the pulse. The MAP sensor allows the PCM to determine engine load in order to calculate the amount of fuel quantity required of the injectors.

Early Vs. Late Lift Pumps

Instead of utilizing a conventional fuel supply system where the injection pump receives a steady low-pressure volume of diesel, the lift pump aboard the 7.3L Power Stroke sends fuel directly into the heads for the injectors to use (remember, fuel is pressurized for the combustion event inside the injector itself). Early engines (’94.5-‘97) came with a cam-driven mechanical lift pump located in the lifter valley that supplied 40 to 70 psi to the injectors (but it usually checks in around 45 psi). Later 7.3Ls (’99-‘03) came with a chassis-mounted electric lift pump that produced 60 to 65 psi, better supported additional horsepower and proved slightly more reliable.

Turbocharger Variations

Three different fixed geometry Garrett turbochargers made it onto the 7.3L Power Stroke throughout its production run. First, a non-wastegated, T4 flange Garrett TP38 with a 1.15 A/R exhaust housing was used on the non-intercooled ’94.5-’97 models. In ’99, a tighter 0.84 A/R exhaust housing and V-band turbine inlet flange was added, along with a wastegate and the use of an air-to-air intercooler. The wastegated TP38 was then replaced by the Garrett GTP38 for the ’99.5-’03 model years, which added a 1.0 A/R exhaust housing, a larger wastegate and a map width enhancement groove. Each version used a 60mm inducer compressor wheel, a 70mm exducer turbine wheel and a 270-degree thrust bearing and journal bearing center section. Despite their differences however, all turbos were oil cooled via the pedestal positioned directly on top of feed and return ports located in the block. This meant that the turbocharger required no external oil lines.

EBP Valve

Another device that seemed ahead of its time in 1994 was the 7.3L Power Stroke’s use of an exhaust back pressure valve (EBP) that served as a choke of sorts for quicker engine warm up. Activated according to engine oil temperature, a butterfly within the EBP housing that’s bolted to the turbocharger’s exhaust housing closes and restricts exhaust flow until the engine is up to operating temp. The PCM oversees the warm up process by way of the exhaust back pressure sensor and slowly adjusts the butterfly back to fully open as oil temperature rises.

Robust Oil Cooler

Another component on the 7.3L Power Stroke that attests to its durability lies in its externally-located fluid-to-fluid oil cooler (mounted below the driver side exhaust manifold). Locating this key component externally aids longevity in virtually any engine, but especially on one that relies on engine oil to fire its injectors and sees considerable engine load by nature of being used as a workhorse. These things virtually never fail. The only things they ever really need are fresh O-rings to quell a slight oil drip, which happens about every other decade. By direct comparison, the internal oil cooler on the 6.0L Power Stroke that was buried in the crankcase would prove extremely problematic, in more ways than one.

7.3L Powerstroke History/Model Year Changes

1994

In 1994, the 7.3L Powerstroke Diesel engine was introduced to Ford’s F-Series truck lineup. This engine could be paired with an E40D 4-Speed Automatic transmission or a ZF 5-Speed Manual Transmission. 1994 7.3L Powerstroke-equipped trucks produced 210 horsepower and 425 lb-ft of torque.

1995

No major 7.3L Powerstroke diesel changes occurred in the 1995 model year.

1996

1996 model year 7.3L Powerstroke-equipped Ford Trucks had higher performance specs than the previous model years. 1996 Ford Trucks with this Diesel engine offered 215 horsepower and 450 lb-ft of torque.

1996 7.3L Powerstroke Mechanical Changes

215 HP 450 lb-ft TQ

1997

California trucks gained split-shot injectors for reduced emissions. Injector Code AB

Performance is increased to 225 horsepower and 450 lb-ft of torque.

1998

No 1998 7.3L Powerstroke-equipped trucks exist. For some strange reason models after 1997 go straight to 1999. We suspect this is because of the massive changes that happened with the 1999 trucks.

1999

1999 marked massive change for 7.3L Powerstroke Diesel engines. This is the first year Ford referred to their F-250/F-350/F-450 trucks as their Superduty lineup. An air-to-air intercooler was introduced as well as many other performance improvements.

1999 Ford Superduty 7.3L Powerstroke Improvements

New Truck Body-style

New 4R110 Automatic Transmission and ZF-6 speed Manual transmissions are introduced.

Larger, split-shot Injectors are used

New Electric Lift Pump

Air-To-Air Intercooler Added

Early 1999 trucks receive a wastegated improved TP38 turbocharger

1999.5+ trucks get a new Garrett GTP38 Turbocharger

1999.5+ Models get a bigger swash plate in the HPOP

All 1999+ trucks receive split shot injectors.

2000

No significant changes occurred in 2000 model years.

2001

In 2001, new 7.3L Powerstroke calibration resulted in a horsepower increase to 250 horsepower and 505 lb-ft of torque on automatic transmission models and 275 horsepower and 525 lb-ft of torque on manual transmission models.

2002

Power levels remained the same this year. The 2,000,000th 7.3L Powerstroke diesel equipped Ford truck hits the assembly line in 2002. This is a testament to the 7.3’s reliability and success.

2003

2003 was the last year of the 7.3L Powerstroke engine being used in Ford Superduty Trucks. Stricter emissions standards resulted in a need for lower emissions and competing manufacturers were designing trucks with similar or better performance capabilities. Ford’s response was the 6.0L Powerstroke engine that was also offered in the 2003 model year.

7.3L Powerstroke Tow Capacity

7.3L Powerstroke tow capacity depends on cab configuration, whether the truck is two-wheel or 4-wheel drive, and whether the truck is a dually or not. Peak 7.3L Powerstroke conventional tow capacity is 12,500 lbs. Peak 7.3L Powerstroke 5th wheel tow capacity is 13,900 lbs. Want to see all Powerstroke towing capacities? Visit our Powerstroke Tow Capacity guide.

OBS 7.3L Powerstroke

Ever seen the term OBS used? OBS means old body style. Ford Superduty trucks with a model year before 1999 feature this old body styling. Therefore, if you see someone referring to an OBS Powerstroke they are referring to trucks from this time period.

In 1999, trucks equipped with the 7.3L Powerstroke gained a new body-style. This makes it hard to identify late model 7.3s as they share the same body style as 6.0L Powerstroke-equipped Ford Superduty Trucks and Excursions. This body style was kept until 2008, when Ford also replaced the 6.0L Powerstroke engine with the 6.4l Powerstroke. New body style 7.3L Powerstrokes are more desirable as they benefit from technological improvements and a more luxurious interior.

This Post Has 0 Comments