The legendary 7.3 Power Stroke Diesel engine, when properly maintained can provide years of trouble…

Understanding the Ford 4.6L/5.4L 3V SOHC V8

I was visiting Ford’s Vehicle Operations (Pilot Plant) in 2002 with a Ford engineering buddy of mine when he decided to show me Ford’s all-new F-150, which was scheduled to debut for 2004. There were several F-150 pilot units on the floor, which had been bucked and built for engineering purposes: proper fitment, function, quality, and shakedown. This is what Ford’s Vehicle Operations in Allen Park, Michigan, does: It does a pilot unit run and checks pre-production vehicles thoroughly to make sure everything fits and works well together at the company’s two F-150 truck plants in Dearborn, Michigan, and Kansas City, Missouri.

When my buddy opened the hoods of these new ’04 F-150 pilot units, it was obvious Ford had a very different Modular planned for the new F-150 and Expedition. It was unlike any Modular SOHC 2V we had ever seen. Power was up for 2004, with a new three-valve 4.6L and 5.4L SOHC Modular engine with variable cam timing (VCT) and improved induction. This new Modular had two intake valves and one large exhaust valve, along with variable-valve timing to help kick power up a notch.

In retrospect, the SOHC 3V engine was something of a crossover engine for Ford. The 3V filled the gap between dated two-valve technology and today’s exciting 5.0L and 5.2L DOHC 4V Ti-VCT Coyote V-8s. The 3V was Ford’s means to getting more power from its low-displacement SOHC V-8s, which were beginning to fall behind global competition.

When Ford introduced the single overhead cam 5.4L 3V Modular V-8 in 2004 in the redesigned F-Series trucks and the 4.6L 3V in the all-new ’05 Mustang GT, it was viewed as an upscale compromise between the 2V Modular and the mighty DOHC-4V Cobra and Mach 1 engines. Three-valve technology bolstered the SOHC Modular engine’s reputation as did variable cam timing (VCT) and charge motion induction. This was weird stuff for the Modular engine family. The SOHC-3V has become a proven mill in the 12 years it has been in production in performance applications like the ’05-to-’10 Mustang GT. The 3V has shown it can take a lot of punishment, make power, and come back for more. It is a fiercely rugged engine.

Because Ford has produced so many SOHC-3V engines since 2004, these mills are plentiful and reasonably priced used and in crate form. There are a lot of them available from crash and theft recoveries. Sometimes, you can snap up the entire vehicle, part it out, and make money on parts for your truck renewal project.

There are aftermarket shops like Modular Motorsports Racing and L & R Custom Engine Building doing complete 3V engines and short-blocks. And because the 3V has an extensive application in the ’05-to-’10 Mustang GT, a lot of parts are available from the performance aftermarket for this engine. If you want to build a 3V from scratch, Summit Racing Equipment has a huge inventory of Ford Performance Parts, as do other aftermarket sources like Roush, Brothers, BBK, Comp Cams, Edelbrock, and more. You can begin with a new aluminum or cast-iron block or the heavy-duty Boss block with larger bores and plenty of material down under to support huge amounts of horsepower and torque. The beauty of a 4.6L or 5.4L SOHC 3V is lightweight aluminum block casting technology. What makes the 3V a better bargain than the 2V is better breathing and more power for the same amount of money as the 2V. It is that second intake valve and variable cam timing that infuse real power into this engine. We’re talking 300 hp at 5,750 rpm and 320 lb-ft at 4,500 rpm of torque box stock in the ’05 Mustang GT. By today’s standard of the 5.0L Coyote, 300/320 horsepower/torque available from the 4.6L/5.4L SOHC 3V is laughable, however, more power is possible with the right parts and technique.

Modular Basics

Ford did something very unconventional with Modular V-8 production. It built the same basic engine family using two different approaches in two engine plants—Romeo, Michigan, and Essex/Windsor, Ontario, Canada. The Romeo factory is the old Ford Tractor Plant, which was shut down and changed over to Modular V-8 engine production in 1990 when Ford sold its tractor division to New Holland. Romeo has produced passenger car V-8s since 1990 with very few exceptions. Those first ’97 F-150 trucks built early in 1996 had Romeo engines because Modular engine production at Windsor was not yet underway.

In 1996, the Windsor, Ontario, engine foundry and plant came on line to produce Modular engines for trucks. Windsor always did things differently than Romeo—this is very important to remember when you’re building a Modular engine of any kind. Not all Romeo and Windsor castings will interchange. Romeo blocks and heads are different than Windsor, which means it is best to stick with Romeo heads on Romeo blocks, and Windsor heads on Windsor blocks for less confusion. The Windsor iron truck block is super rugged with dowel-pin cross bolt or interference fit main caps.

Because this article is about the Ford SOHC 3V engine, we’re going to focus attention on what makes this engine different than the SOHC 2V it replaces. Production of the 2V engine continued well into 3V production because the 3V wasn’t available in all vehicle types. The 3V was never factory installed in a Crown Victoria or Grand Marquis. It never saw use in the E-Series Econoline vans, either. If your hardworking F-Series truck has the SOHC 3V engine, there’s a lot of good information here for you.

The Ford SOHC 3V Modular engine was produced with both cast-iron and aluminum blocks, depending on model year. In fact, the Modular block is so versatile you can use any of these blocks for your 3V build. This includes the early aluminum Teksid Cobra blocks. For a work truck, it is best you stick with the block type (iron or aluminum) Ford originally installed in your truck or sport utility.

Block Bottom

According to George Reid’s How to Rebuild 4.6L and 5.4L Ford Engines book from CarTech Books, there are several 4.6L and 5.4L iron and aluminum block castings to choose from. In the end, it boils down to Romeo versus Windsor cast-iron blocks, then, the aluminum blocks. Windsor 4.6L iron blocks are identified with a “W” and dowel pins at the cross-bolted main caps. Romeo 4.6L iron blocks are identified by an “R” and jackscrew cross-bolted main caps. Not all Romeo blocks will have an “R”.

Although the Romeo and Windsor block castings are basically the same in appearance, it is suggested you stick with the Windsor block for your truck. The 5.4L iron block was cast, machined, and assembled at Windsor only. The 4.6L iron block was produced at both Romeo and Windsor.

At a glance, it is challenging to tell the difference between a 4.6L iron block and a 5.4L. Where these blocks differ is deck height with the same cylinder bore size. The 5.4L block has a taller deck. It is also long on beefcake down under for strength. At the front of the block, core plugs are further away from the deck on the 5.4L than we find with the 4.6L. Sides of the block are deeply ribbed with the 5.4L for strength.

All 4.6L and 5.4L SOHC Modular engines employ the same basic blocks, meaning you can bolt any SOHC 3V head on any Romeo or Windsor block, which gives you a lot to choose from. Romeo iron blocks were cast at the Cleveland Iron Foundry (CF). Windsor iron blocks were cast at the Windsor Iron Foundry (WF). Aluminum blocks were cast at the Windsor Aluminum Plant (WAP), unless you’ve found an older DOHC 4V Teksid block, which was cast in Turin, Italy, in the ’90s.

Aluminum blocks are as universal as iron in that you can bolt 3V heads to any of them. We suggest you opt for newer Ford aluminum blocks and stay away from the early Teksid castings only because there’s virtually no benefit to using these vintage castings in a truck application and they can get expensive. Ford brought aluminum block casting in house in 2001. Although this can be endlessly debated, the Ford “WAP” (Windsor Aluminum Plant) block casting is said to be stronger than the Teksid block.

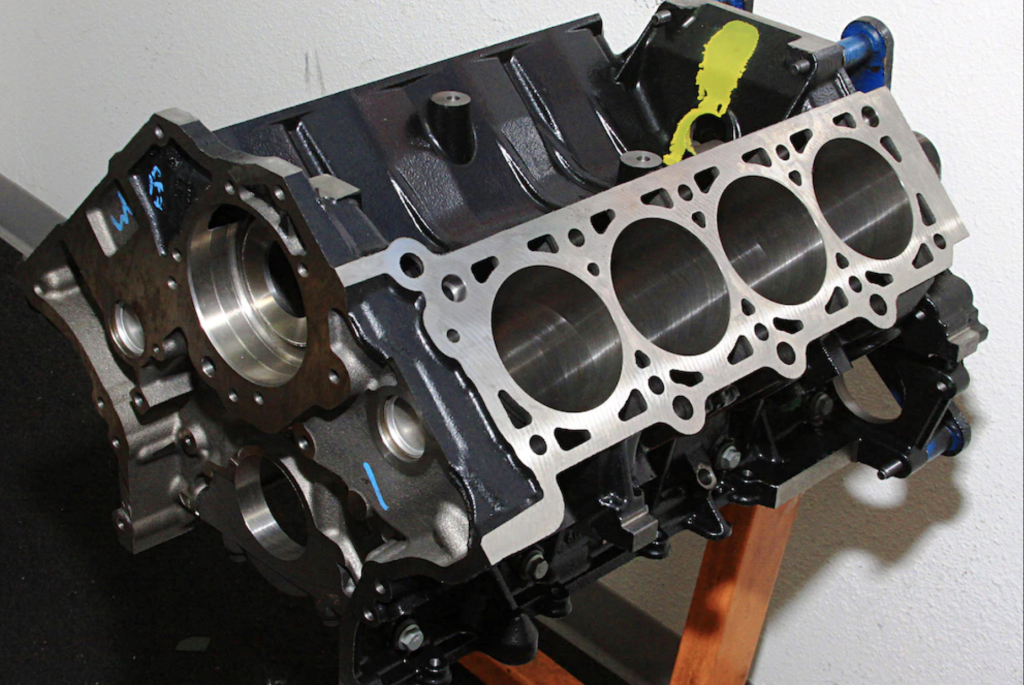

Here’s a new Romeo iron block suitable for any SOHC 2V or 3V Modular engine build. There are ample cores new and used for your Modular engine build. Romeo blocks are quickly identified by the valley drain hole at the back of the block. Windsor blocks do not have the valley drain. Also look for a “W” on Windsor blocks and “R” on Romeo blocks. Not all Romeo blocks will have an “R” in the casting.

Newer Modular blocks have interference-fit main caps void of jackscrews and dowel pins. If you have the budget and the time, this is the block you want.

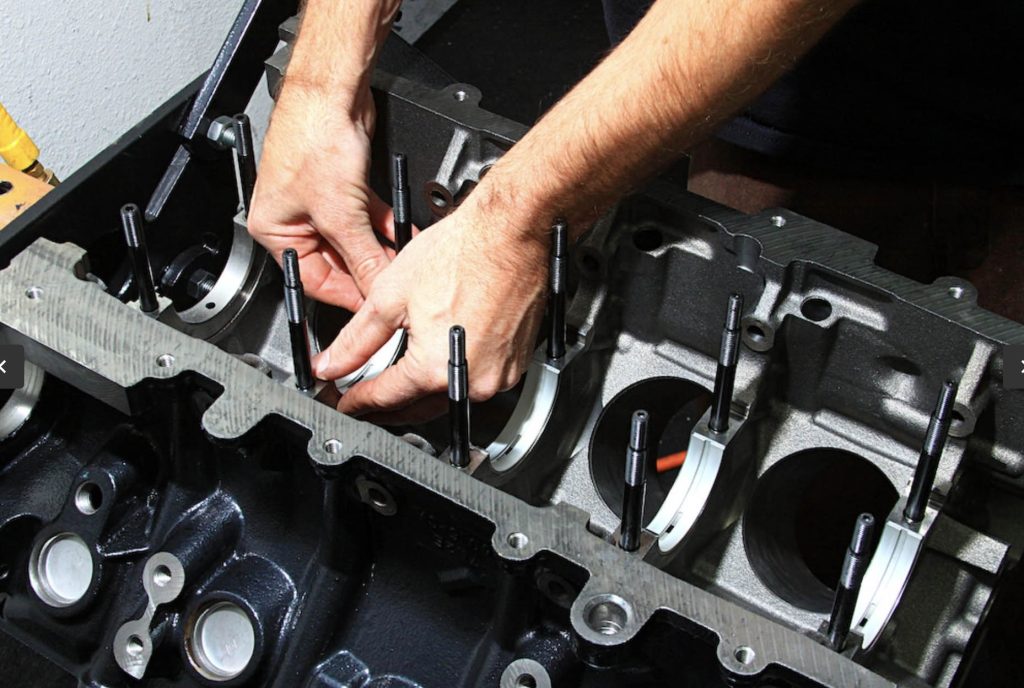

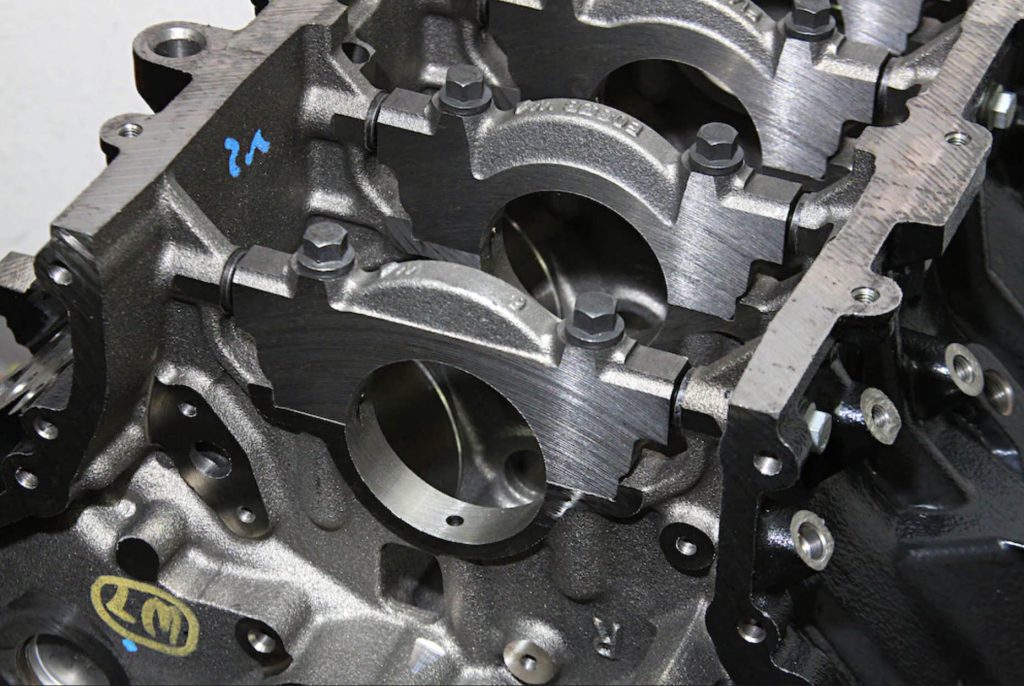

It is suggested you stud and bolt main caps using ARP fasteners for optimum results. We associate studding with racing engines, however, ARP studs offer unequaled main bearing cap security. Opt for ARP fasteners throughout your 3V build.

All Modular engines call for the use of aluminum main and rod bearings. When you install bearings, keep fingertip contact to a minimum, touching only the bearing ends. Skin oil contaminates bearing surfaces. Bearings and journals must be hospital clean.

Modular engines were produced with six- and eight-bolt crankshafts. Truck and high-performance applications were fitted with the eight-bolt steel crankshaft (left). Six-bolt cranks (right) were common with Romeo passenger car engines.

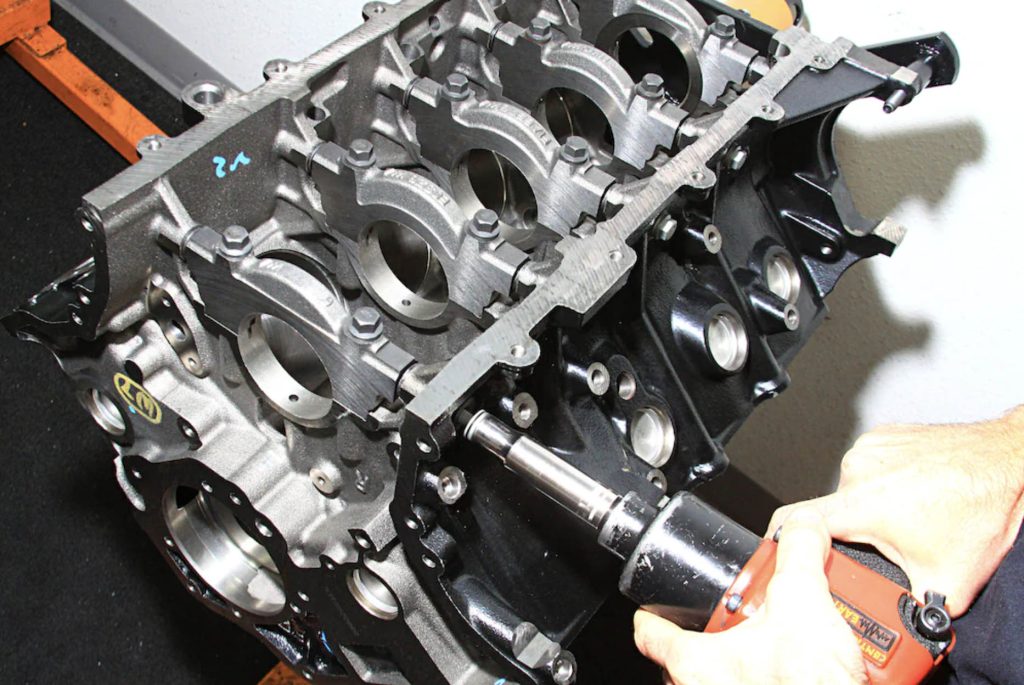

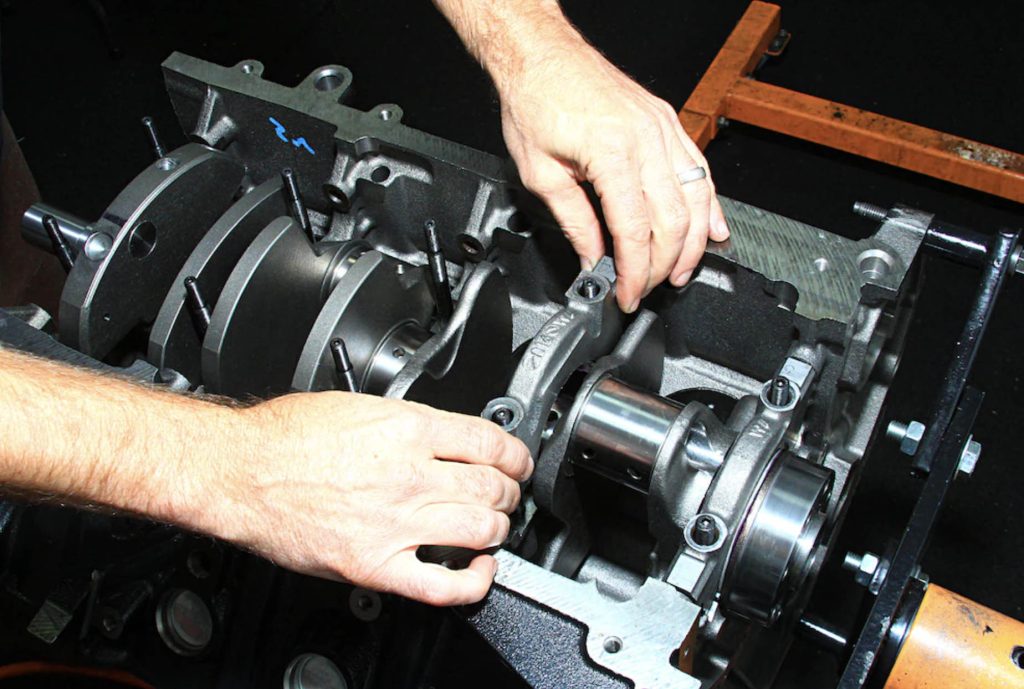

The 3V’s cross-bolted main caps are set first and torqued to specifications before cross bolts are installed and torqued. Romeo engines have jackscrews, which are screwed out to proper torque before bolts are installed. Windsor engines have dowel pins, which are set before cross bolts are installed. Newer Modular blocks are an interference-fit void of jackscrews or dowels. Main caps are set and torqued, then cross bolts installed.

Modular engines were fitted with forged pistons from the factory, which caused cold knock or rap (piston slap). There’s no need to go to the expense of forged pistons in your 3V when hypereutectic (high silicon) cast work just as well in a truck application. Cracked powdered metal connecting rods arrived with the Modular engines in 1991. Though “powdered metal” sounds wimpy, it’s actually a high-tech way to forge a connecting rod. These rods can be reconditioned and fitted with oversized bearings. They are incredibly strong. If you are faced with having to replace the stock rods, you’re better off going with a set of heavy-duty I or H-beam aftermarket rods, which are actually cheaper than stock rods from Ford. On average, stock rods cost $60 to $80 each.

Modular engines sport low friction rings (thin) for improved efficiency. This is a forged and coated Modular Motorsports piston from Manley for a high-performance engine build.

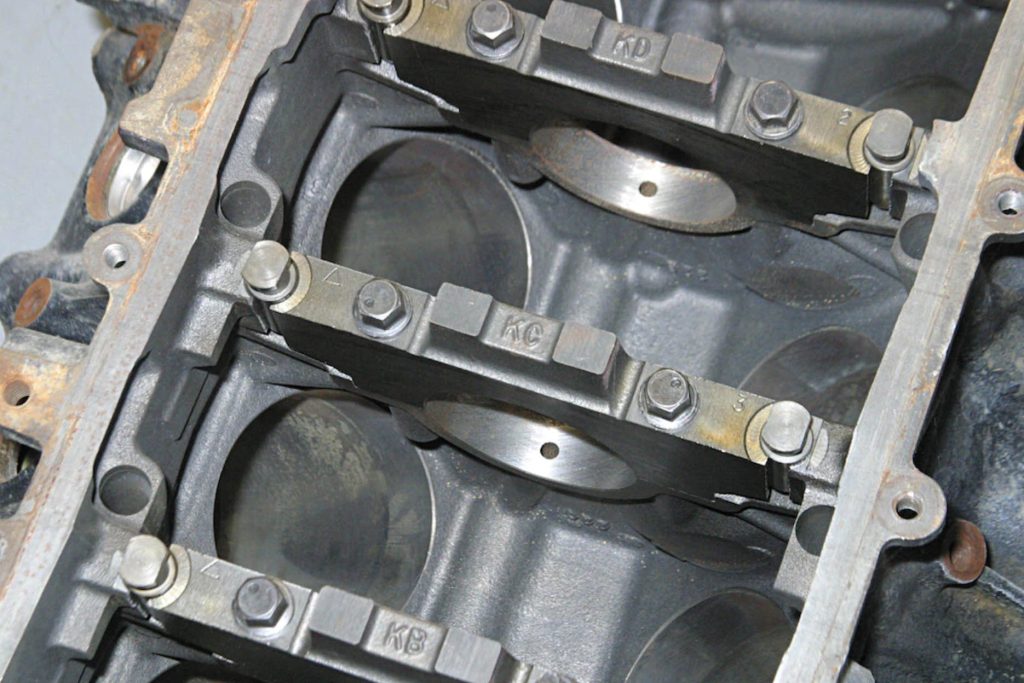

Romeo blocks are fitted with jackscrews and cross bolts for main journal support. Newer Romeo blocks are interference-fit without jackscrews.

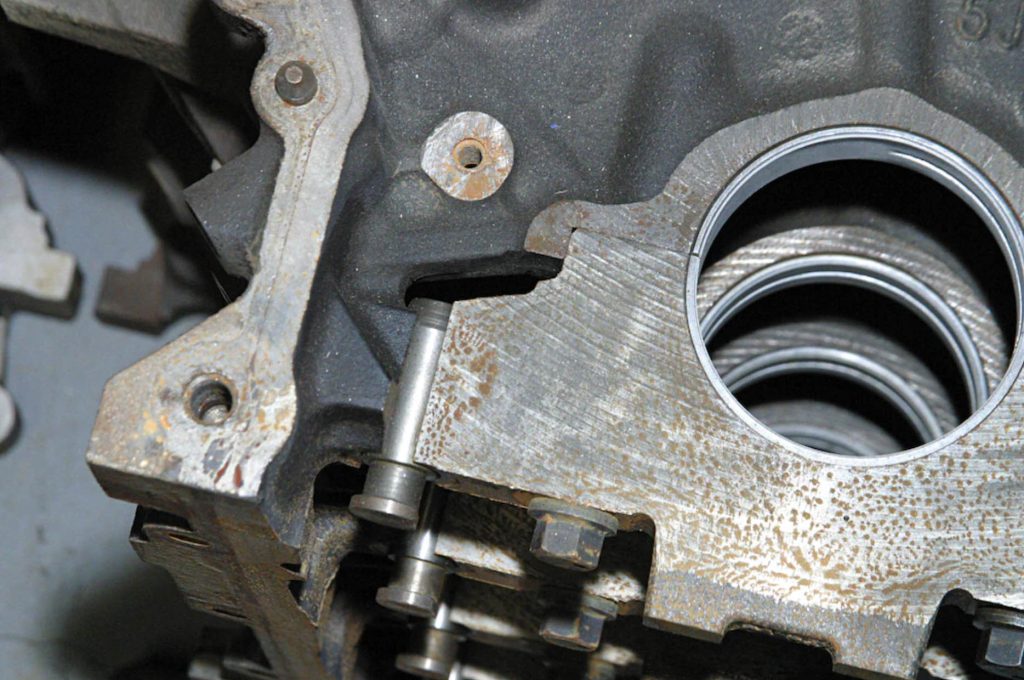

Windsor blocks were fitted with dowel pins instead of jackscrews. As with Romeo blocks, newer Windsor blocks are an interference-fit and void of dowel pins.

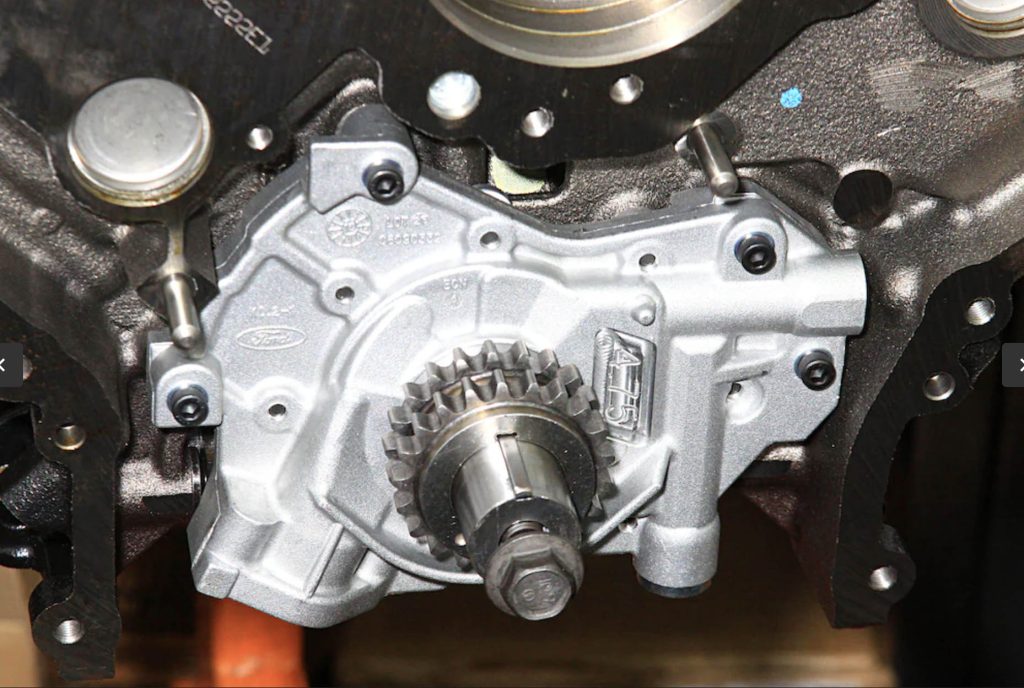

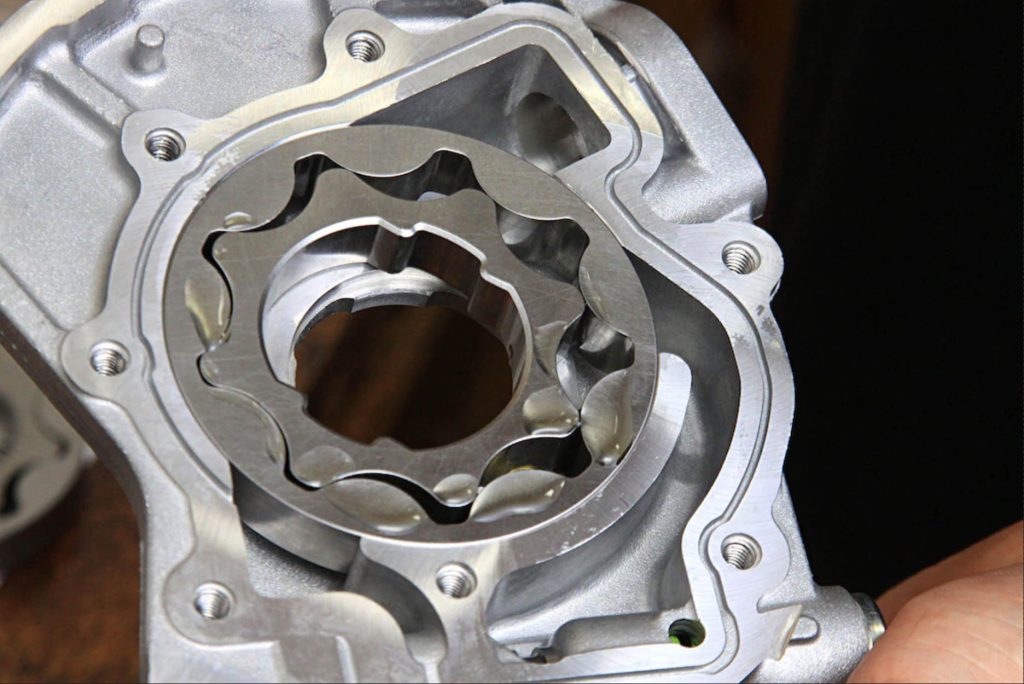

All your 3V Modular engine needs is a high-volume oil pump with hardened steel internals for durability. These are available throughout the aftermarket.

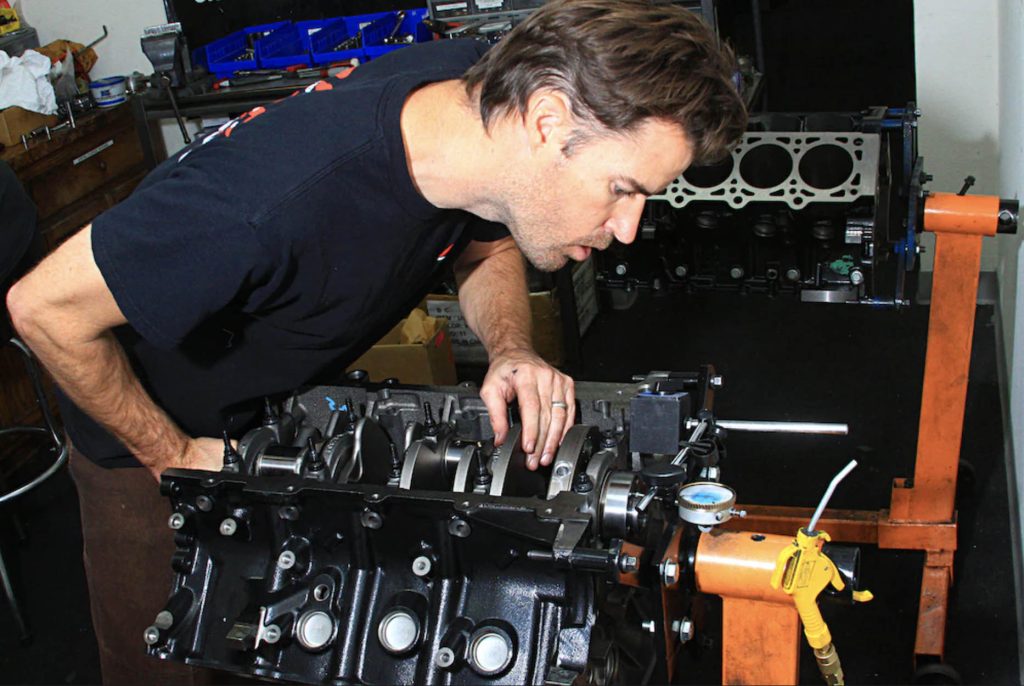

Assembly should be hospital clean. Ensure you have dust-free components. Use a high-evaporative solvent like brake cleaner for oil galleys and bolt holes. Always bag the engine when work isn’t in progress.

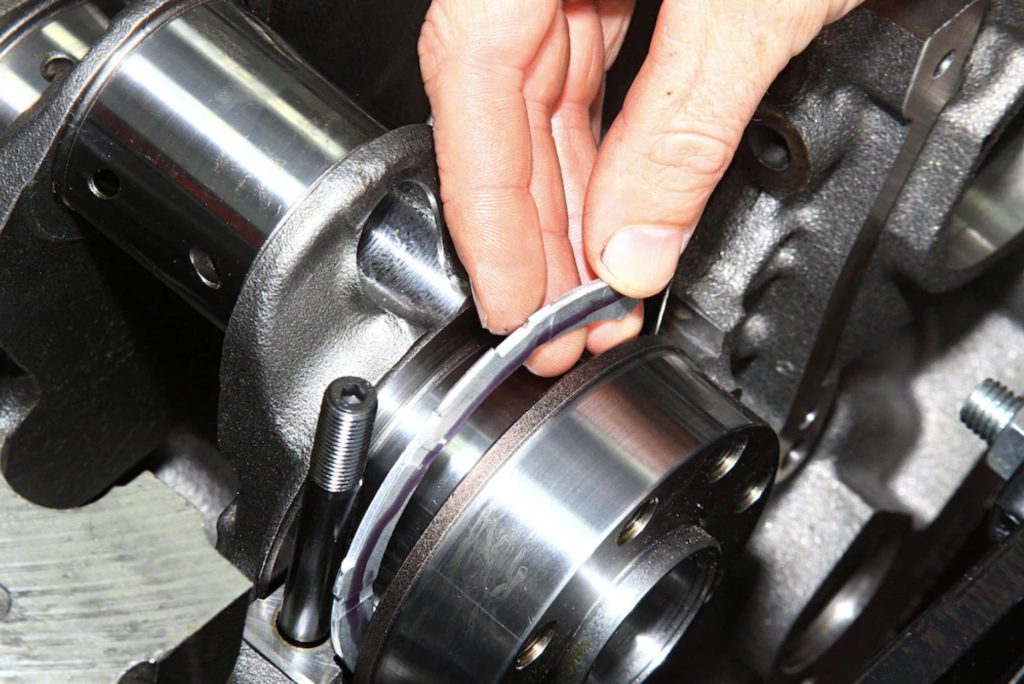

Crankshaft endplay is determined by this thrust bearing, which is available in various thicknesses. Whereas Ford engines have always had the thrust bearing at #3 main journal, the Modular’s thrust is at #5.

It’s a good idea to spray down cylinder walls with WD-40 to prevent corrosion and when you’re doing a cylinder wall wipe down with a tack cloth prior to piston/connecting rod installation. Never use a shop towel on engine parts. Always use a lint-free tack cloth.

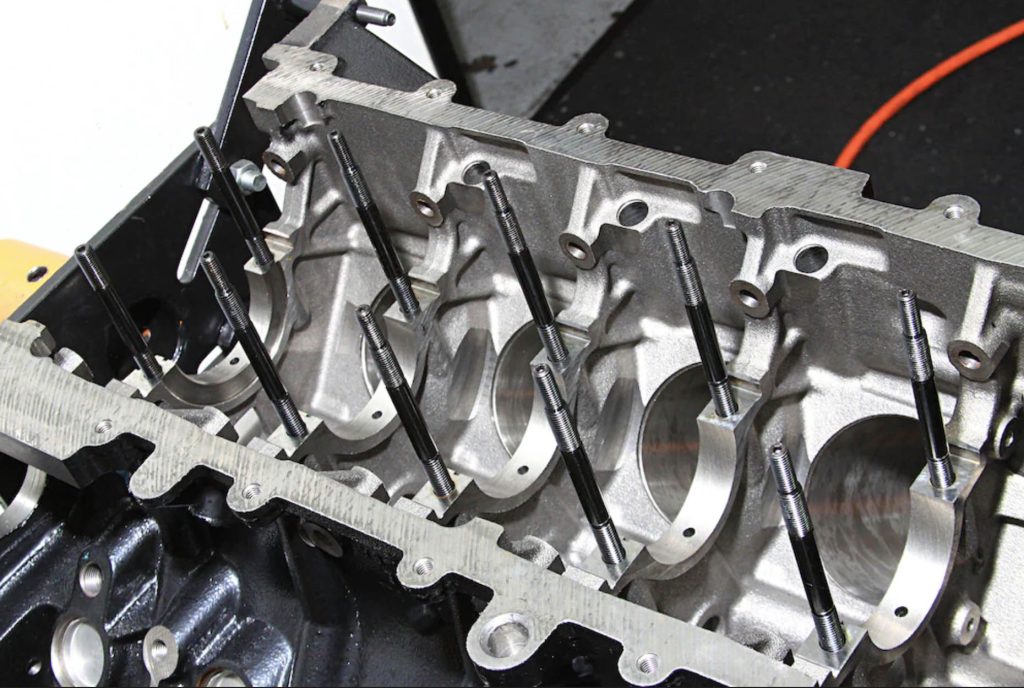

Optimum cylinder head and gasket security comes from the use of studs instead of bolts. The downside of studs is cylinder head removal. It cannot be performed in the vehicle with studs because the cylinder head will not clear the cowl. The engine must be pulled. Because the Modular engine uses torque-to-yield fasteners, they must be replaced with new versions.

Cylinder Heads

The SOHC3V cylinder head is completely different than the 2V, thanks to its innovative, apex-shaped combustion chambers and two intake valves engineered to improve velocity and volume. One large exhaust valve handles scavenging. The spark plug is centrally located for a more uniform light-off. Early 3V heads have a serious problem with spark plug firing tips that break off in the cylinder head. This problem was solved by Ford by 2008. Early heads call for the use of a special tip removal tool, which makes it possible to remove the firing tip with the head installed.

This head makes more power than the 2V head and is a close runner-up to the 4V. When you take this improved airflow port and valve design and marry it to variable cam timing (VCT), you have a great formula for power without additional cams and valves. VCT moves the cam on its longitudinal axis to advance or retard valve timing to improve both performance and reduce emissions. When you advance valve timing, you gain low-end torque, but usually at the cost of high-end horsepower. And when you retard valve timing, exactly the opposite happens, with losses in low to mid-range torque and gains in horsepower. With VCT, you get the benefit of both without sacrificing power. Down low, you get more torque because VCT advances valve timing. And with the pedal to the metal, VCT retards valve timing to help you achieve more horsepower.

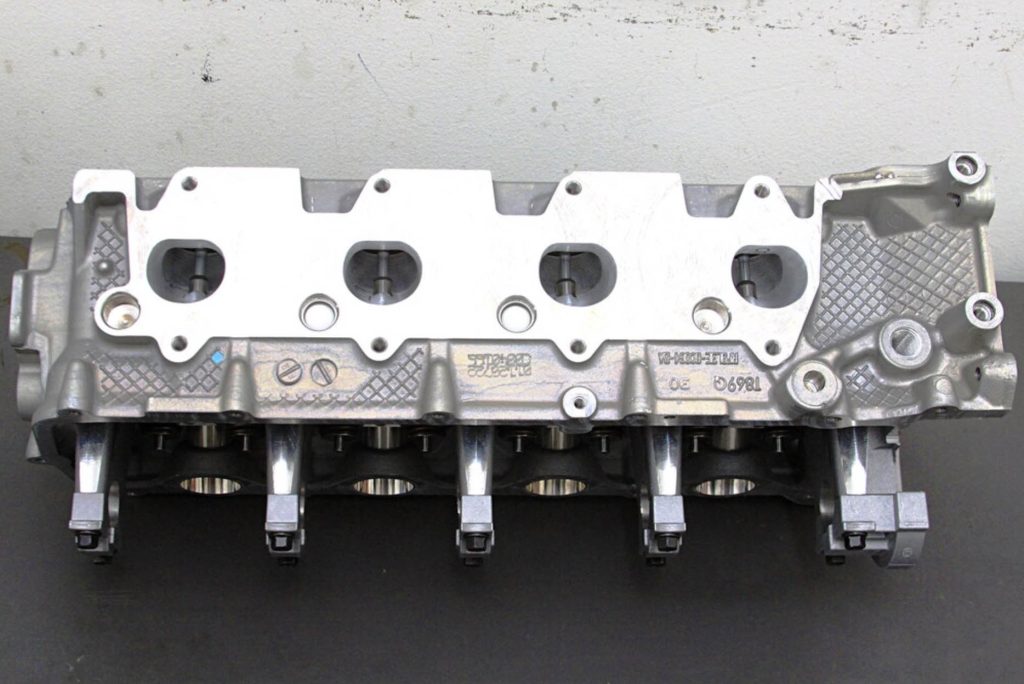

VCT is accomplished via a solenoid-operated metering valve at the front of each cylinder head. Each solenoid is activated by the PCM/ECU, depending on driving demand. Unlike the 2V engine, the 3V head is right- and left-specific. The stock 3V head offers good airflow right out of the box at 174cc intake runner volume and 62cc exhaust with 51cc chambers. Flow at 0.600-inch lift is 225 cfm and exhaust is 195.7 cfm box stock.

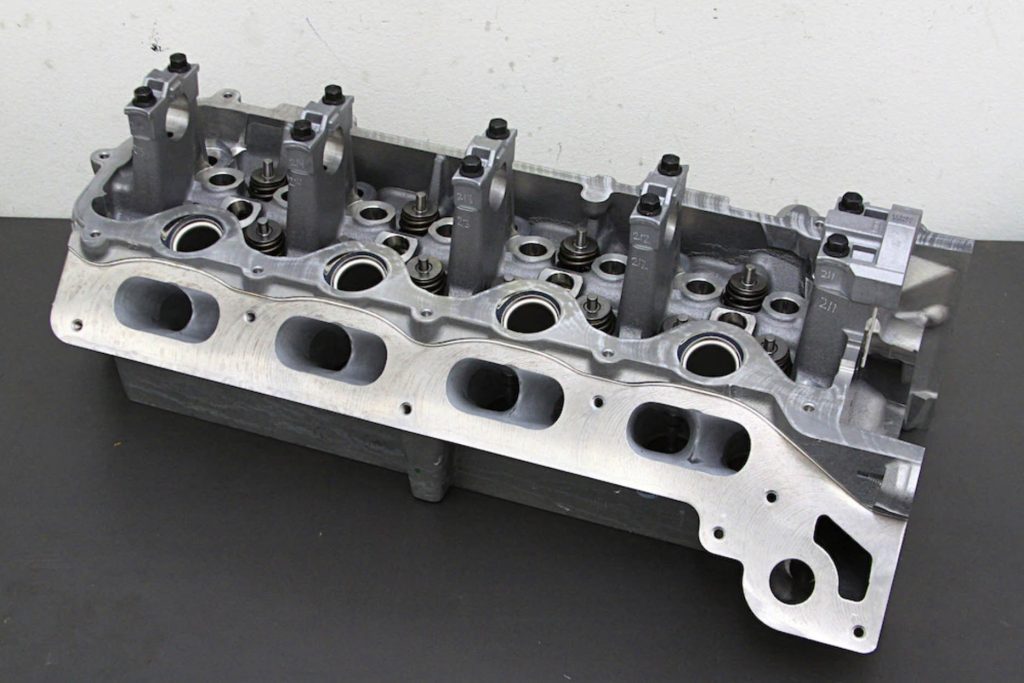

This is the 3V head with twin intake ports (twinport) flowing into two 1.338-inch (33.8mm) intake valves. The 3V is a traditional Windsor-style head with standalone journals like the Windsor 2V head. VCT oil passages (arrow) are shown here at the front of the head.

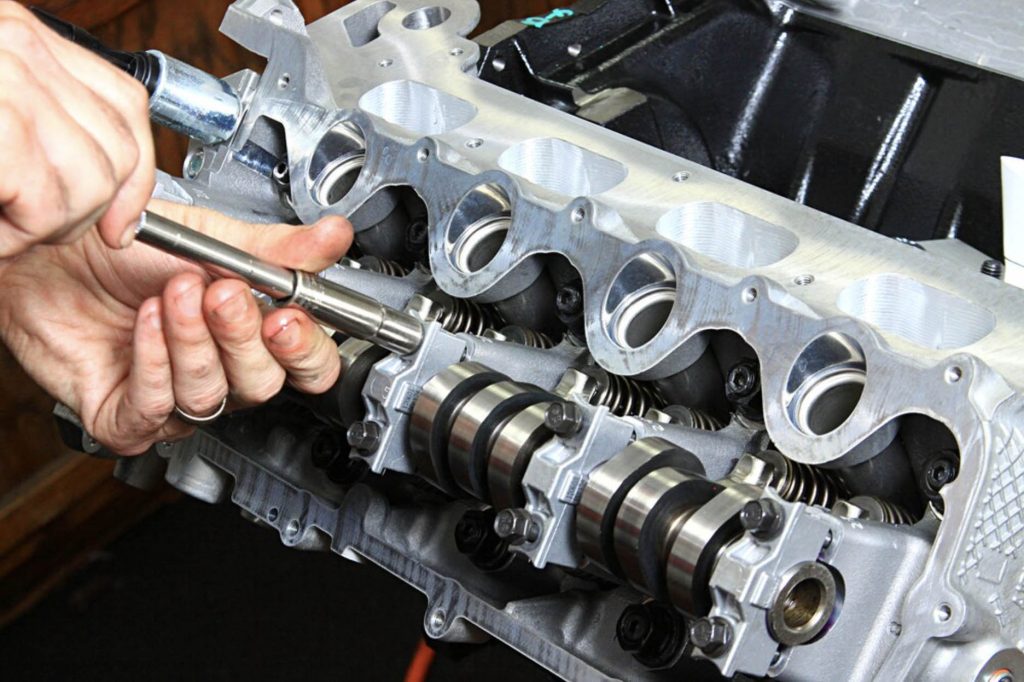

This is the three-valve configuration as it appears without rocker arms and cam installed.

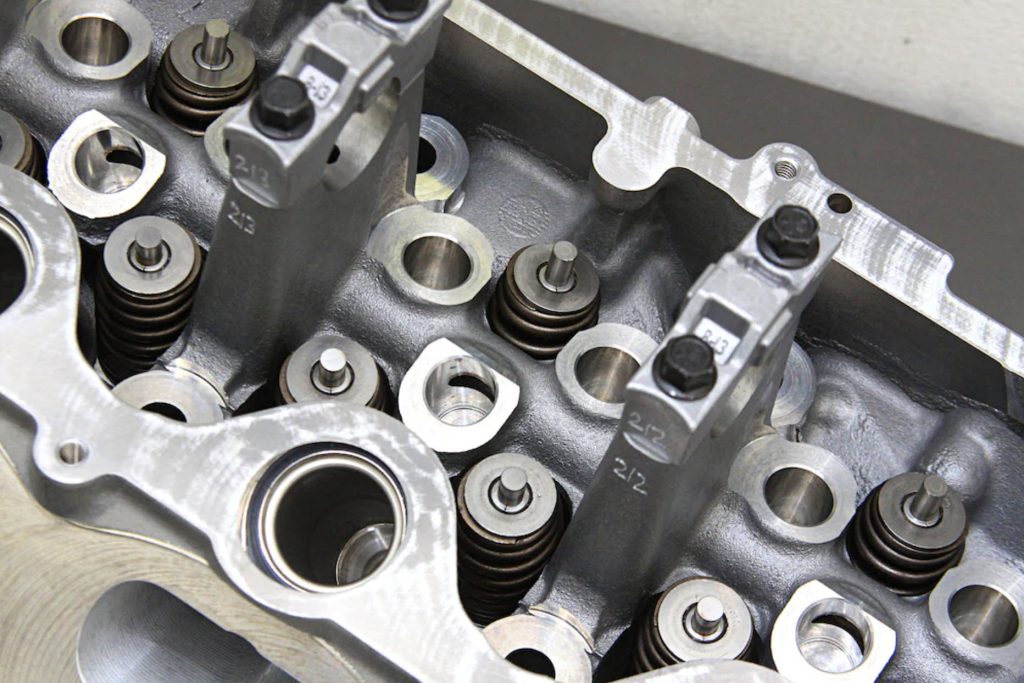

Here is the 3V apex-shaped combustion chamber with its twin intake valves, single large exhaust valve, and centralized spark plug.

D-shaped exhaust ports offer improved flow and velocity for improved scavenging.

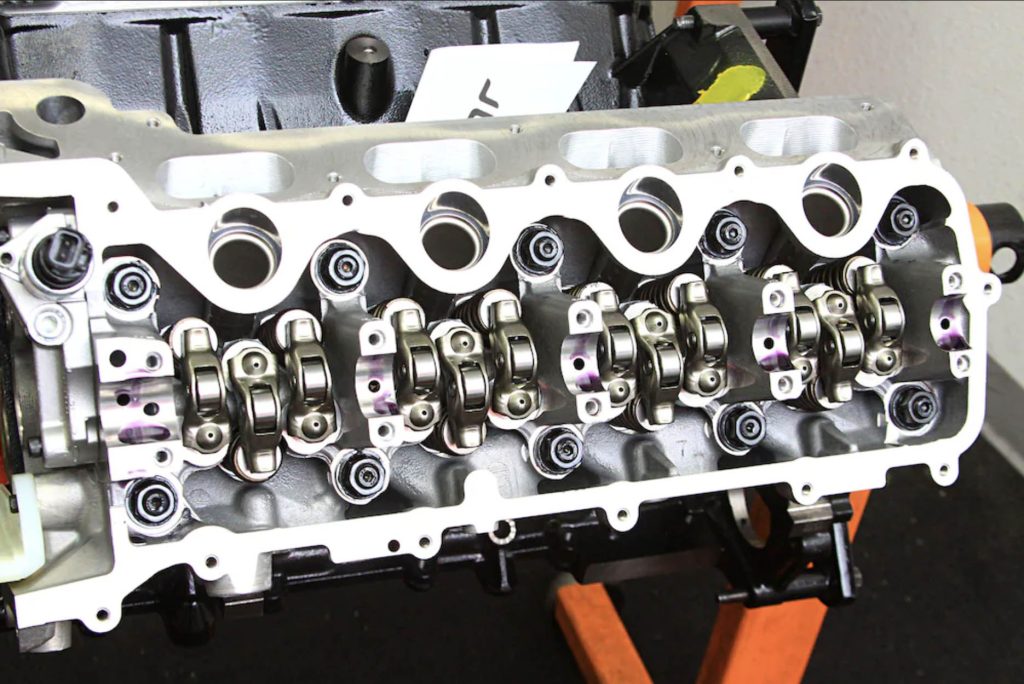

Immediately recognizable are 12 roller rocker arms for eight intake valves and four exhausts, actuated by a single overhead cam on each bank.

This is the VCT solenoid valve, which advances valve timing via a signal from the PCM/ECU as required. This valve vectors oil pressure to the VCT cam sprocket on each head known as a phaser, which advances the cam.

Cam installation requires patience and close attention to detail. Cam journals must be tightened slowly in proper order per the Ford Shop Manual until each is seated, then torqued to specifications. Never tighten one journal all at once. Because these are torque-to-yield bolts, they must be replaced. We suggest the use of ARP cam journal bolts, which are not torque-to-yield and can be torqued the old-fashioned way.

These are the 3V’s VCT cam sprockets. The five reluctors pass a cam sensor on each bank, which triggers the PCM/ECU and variable cam timing. These sprockets are also actuators, which rotate (advance) the cams via solenoid-controlled oil pressure. These sprockets are left- and right-specific. Look for the “L” and “R” markings on each.

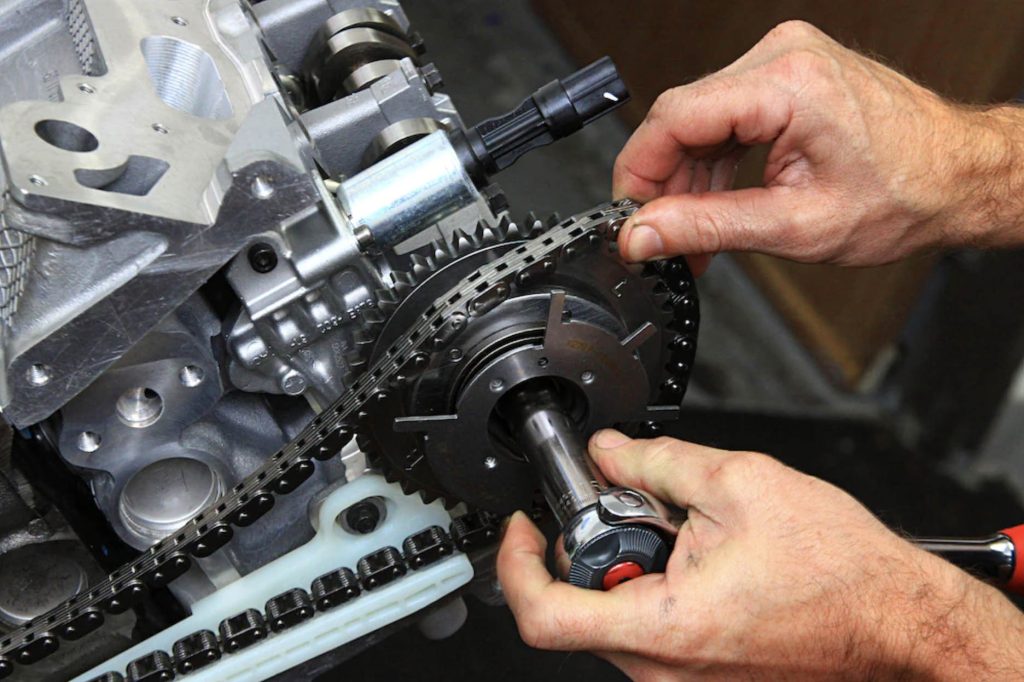

Timing chain installation on these engines is easier than it appears. Each chain has dark color timing links, which are matched to timing marks on each sprocket per your Ford Shop Manual. Install the chains, then the oil pressure–supported tensioners. You may have to ever so slightly move crank and cam sprockets to get these marks lined up. Keep crank and cam movement modest. Too much movement can lead to bent valves.

Romeo and Windsor engines do not share the same chain guides. Romeo chain guides look like this (nylon-lined steel with different bolt holes than a Windsor). Never use Romeo guides on a Windsor engine and vice versa. They do not interchange.

Windsor engines are fitted with these chain guides. Fixed guides are plastic. The floating guides are similar to Romeo, but not the same.

There are two basic types of crankshaft reluctor wheels used on both Romeo and Windsor engines. Earlier Modulars used solid-steel reluctor wheels. Later Modulars employ this stamped-steel reluctor wheel. Teeth must point toward the timing cover and away from the engine block. If you install this reluctor wheel with the teeth pointed toward the engine, it will cause chain damage and engine failure.

Two types of harmonic dampers were used on Modular engines —six- and eight-rung. Windsor truck engines were eight-rung. Examine your damper and count rungs before ordering a new one.

This Post Has 0 Comments